There’s been a trend of late among North American toy manufacturers to either move manufacturing back home or to stay put entirely. Recently, I had a chance to visit the Mega Bloks factory in Montreal, where Mega Bloks—the signature toys of Mega Brands Inc.—are produced, and it only strengthens the argument not to export toy-making abroad. Jean-Francois Albert, vice president of manufacturing for the company, offered a guided tour that showed off the facility’s various innovations, which keep it cost-effective, even compared to China and other countries that traditionally offer cheap labor.

There’s been a trend of late among North American toy manufacturers to either move manufacturing back home or to stay put entirely. Recently, I had a chance to visit the Mega Bloks factory in Montreal, where Mega Bloks—the signature toys of Mega Brands Inc.—are produced, and it only strengthens the argument not to export toy-making abroad. Jean-Francois Albert, vice president of manufacturing for the company, offered a guided tour that showed off the facility’s various innovations, which keep it cost-effective, even compared to China and other countries that traditionally offer cheap labor.

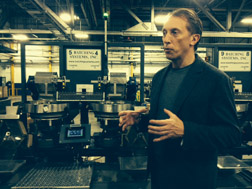

My visit coincided with the low season. Nevertheless, the factory was humming, especially the molding department, which featured two seemingly endless rows of plastic injection machines, which make blocks out of resin pumped in from large silos outside. According to Jean-Francois, this part of their operations benefited from a $35 million investment over the past three years, and as a result, 12 of the injection machines are fully electric compared to the older hydraulic models, which use a combination of oil and electricity. They run 40 percent faster, use 40 percent less power, and produce 40 percent more blocks per hour.

My visit coincided with the low season. Nevertheless, the factory was humming, especially the molding department, which featured two seemingly endless rows of plastic injection machines, which make blocks out of resin pumped in from large silos outside. According to Jean-Francois, this part of their operations benefited from a $35 million investment over the past three years, and as a result, 12 of the injection machines are fully electric compared to the older hydraulic models, which use a combination of oil and electricity. They run 40 percent faster, use 40 percent less power, and produce 40 percent more blocks per hour.

(Click here to see video of an injection machine at work.)

But the factory’s pride and joy might be a new counter machine that was several years in development. On the top is a chamber of light, which the blocks fall into, and depending on the shadow cast by the blocks, the machine knows if there is one, two, or more blocks inside. It is customized to count a certain number, and then drop its contents into a passing bucket below. A line of these counting machines is set up on the factory floor, filling buckets with the right combination of blocks for each package of Mega Bloks. At each counter, nearly 600 bags of Mega Bloks can be assembled in an hour.

The buckets eventually make their way to the bagging department, which ensures each clear bag contains the right combination of blocks, that there aren’t too many or too few, etc. As each of the factory’s bagging lines produces roughly 1,500 bags per-hour, it is the responsibility of a worker to open certain bags and compare them to an official “recipe.” Since Mega Bloks’ counting machines are so precise, all of the bags in a batch should be identical to one another, so that if one passes inspection, the rest should as well.

Other cost-saving innovations include hot runner molds that waste less plastic, and lights in the adjacent warehouse that only activate when someone walks through, the latter of which saves an estimated $100,000 per-year. In addition, the factory runs on hydro-electricity, which uses 40 percent less energy than a factory running on alternative forms of electricity.

Although not every part of the toy is made in Canada—it is more cost-effective to have highly-detailed and electronic components made in China and shipped over—as far as productivity and carbon footprint are concerned, Jean-Francois says there’s no comparison between that country and this one. “We can produce six times more toys than a Chinese factory, using the same amount of energy and generating 500 times less carbon dioxide gases in the process,” he says.

In closing, the Mega Bloks factory is impressive: lean, green, and clean. Now I’d be remiss if I didn’t make any mention of Mattel, which announced it was acquiring Mega Brands back on February 28. At the time of my visit, my hosts could not comment as to whether the purchase would affect the future of the factory, production volumes, schedules, etc. But if I could offer my own two cents, based on what I saw, I would advise Mattel to take a long, hard look at the innovations in Montreal, and to consider expanding them to their other facilities.

After all, no matter where the toys are manufactured, anything that makes the toy industry a better global citizen can’t be a bad thing.

For more commentary from Phil, check back often. Views expressed in this column are solely those of the author and do not necessarily reflect the views of The Toy Book as a whole. We hope that you will share your comments and feedback below. Until next time!