Mattel is reinventing its Matchbox brand with eyes toward a sustainable future.

Ahead of Earth Day, the company unveiled its “Drive Toward a Better Future” product roadmap to make all Matchbox die-cast cars, playsets, and packaging with 100% recycled, recyclable or bio-based plastic by 2030. The move comes as part of Mattel’s long-running goal to achieve those same goals across all of its product lines.

“Since the inception of the modern-day die-cast car nearly 70 years ago, Matchbox has been using design and innovation to connect kids with the real world around them through play,” says Roberto Stanichi, global head of vehicles at Mattel. “Matchbox is committing to using 100% recycled, recyclable or bio-based plastic materials to do our part in addressing the environmental issues we face today, and empower the next generation of Matchbox fans to help steer us towards a sustainable future.”

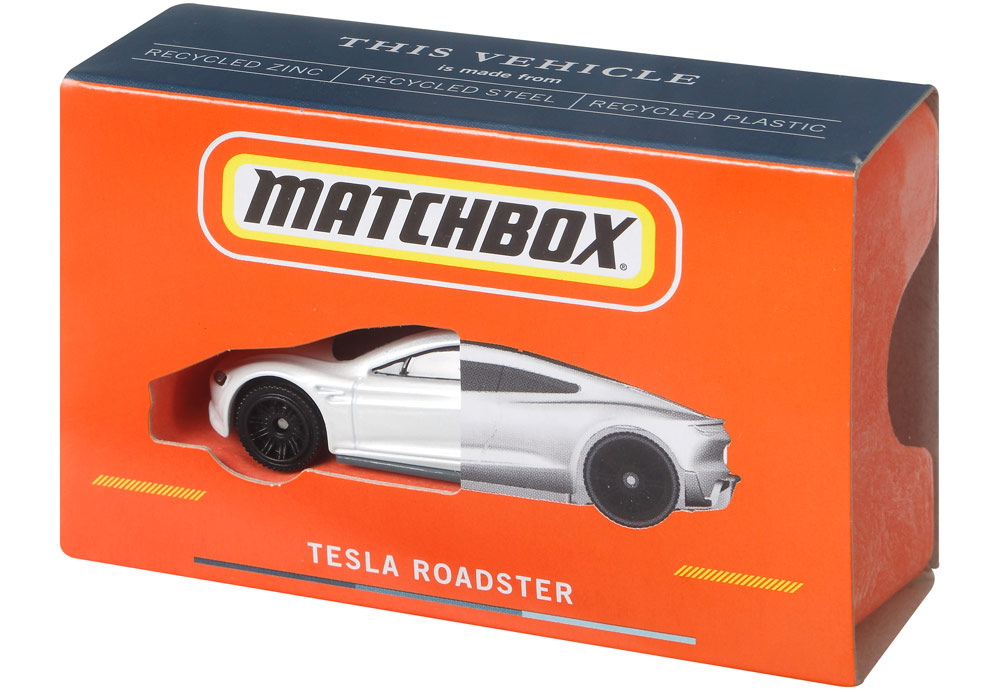

For a glimpse at the future, Mattel dropped the curtain on its Matchbox Tesla Roadster — its first die-cast vehicle made of 99% recycled materials, including zinc, steel, and plastic. The Tesla Roadster has been certified CarbonNeutral and will be available next year.

Mattel recently released an EV-themed five-pack of 1:64-scale Matchbox vehicles that ships with a paper foam inner tray. The first product line under the Matchbox brand to ship plastic-free is the current Power Grabs assortment.

An environmentally conscious approach will be taken across the entire brand, not just in packaging materials, but also in the play pattern as well. While the Hot Wheels brand leans largely toward fantastic, imaginary scenarios, Matchbox has long been known for presenting real-world vehicles and locations. Mattel says it plans to offer more e-vehicles in its die-cast lineup while adding pretend charging stations to its fuel station playsets.